The best ingredients for the best beer

It isn't just our centuries-old brewing tradition that makes our Mönchshof speciality beers taste so unique. Another reason is our ingredients that must satisfy our own high standards before we use them in our brewing process. You can find out more on this page!

![[Translate to Englisch:] Weiße Illustration Zutaten](/fileadmin/user_upload/Illustrationen/_0000_illu_zutaten.png)

Special selection of ingredients

It goes without saying that we only use the ingredients that were set down in the Bavarian purity law in 1516: Malt, hops, water and yeast.

But not every malt and all hops are suitable to be ingredients in our speciality beers. As with good cooking, choosing special ingredients and putting them together the right way makes the difference.

The fact that we can create so many nuanced flavours in our brewing is mainly down to our pure, soft water from the Fichtel Mountains, hundreds of different varieties of malt and hops from our trusted partners and our own purebred yeast. We hardly use any bitter hops. Freedom from GMOs is second nature to us. With our high standards, special malt blends of the highest quality meet premium aromatic hops from Hallertau to become speciality beer from Mönchshof.

Would you like to find out more about specific ingredients and their importance in the brewing process? You’ll find more information here:

Malt – the body of the beer Hops – the soul of the beer Yeast – the flavour of the beer Water – the basis of the beer1.0 Malt – the body of the beer

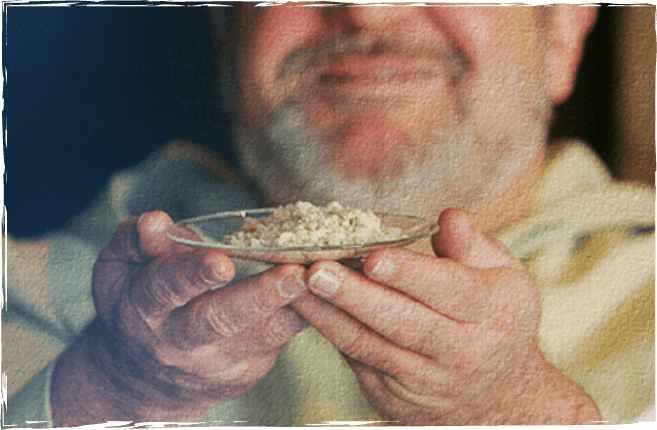

Freshly flailed malting barley is delivered to our Franconian malting partners straight from the field. The grain is processed into strong special malts in a series of different steps depending on the malt variety.

The first step is to soak the barley in water until it begins to germinate. After around 5 to 7 days, germination is stopped with gentle drying and the germ bud removed. The malt is now ready for storage and can be ground.

In beer brewing, the malt blend recipe determines the later result. Along with basic malts such as the light Pilsner malt, Viennese malt or Munich malt, there is a variety of gently roasted caramel speciality malts, aromatic malts, smoky malts or roast malts to choose from. The malt blend used is what determines a beer’s character and colour.

1.1 Some of the most popular malt varieties

1.2 Malt and beer colour

The different malt varieties have a particular effect on the flavour of the finished beer. The colour is also largely decided by the malt varieties added.

A beer’s colour is measured using the EBC scale. In Europe, the unit EBC is used to measure the colour strength of beer and/or beer wort. The value set by the European Brewery Convention specifies how much light is absorbed by beer with a specific original wort content. The more light is absorbed, the higher the EBC value and the darker the beer.

2.0 Hops – the soul of the beer

Hops preserve beer and give it its unmistakable, bitter flavour. Depending on the type and quantity of hops added, this ingredient, along with malt, largely determines the finished beer’s flavour and odour.

In addition to the specific production and composition of the malt varieties, the individual combination of the selected hop varieties is also crucial to Mönchshof speciality beers’ uniqueness.

Over 100 hop varieties are cultivated all over the world and this number is increasing. This might even be down to the craft beer movement’s willingness to experiment. Whereas people used to value bitter-tasting hops, today’s beer connoisseurs prefer the variety of hop aromas with fruit, herb or grass flavours.

2.1 Aromatic hops not bitter hops

Hops contain two crucial ingredients: Bitter compounds and aromatic compounds. While classic bitter hops (with bitter compound content of over 10% alpha acid) are added to the wart at the beginning of boiling and give the beer its classic, slightly bitter flavour, we at Mönchshof prefer the sensory effect of selected varieties of aromatic hops. These blends make our speciality beers’ flavour and bouquet even more multifaceted.

Aromatic hops have a higher content of bitter compounds of 10% but a lower content of essential aromatic oils (below 0.5%). The individual addition of hops is also mainly done at the end of boiling so the hop aroma doesn't really have a chance to evaporate.

2.2 German fine hops for beer with superlative flavour

German fine hops from the cultivation areas Hallertau, Elbe-Saale, Tettnang and Spalt are world famous and, in many cases, the ancestors of many foreign new breeds.

Hops have been cultivated in Hallertau since the eighth or ninth century. At around 14,100 ha, the region is the largest continuous cultivation area in the world. The specific climactic and soil conditions, as well as centuries of knowledge, have contributed to the region being responsible for one third of the world's hop production.

The umbels from the 7 m tall hop plants are harvested from the end of August and immediately made into high-quality hop products in regional processing plants.

2.3 The most important aromatic hop varieties

2.4 Hops and sensory bitterness

The bitterness unit indicates the quantity of bitter compounds in a beer variety. This "bitterness" comes directly from the type and quantity of hops added.

The following principle applies: the higher the bitterness unit (IBU – International Bitterness Unit), the more bitter the beer will taste. However, the subjective impression falls as malt content rises so darker beers usually have higher IBU than you would expect from the taste.

3.0 Yeast – the flavour of the beer

Like must becomes wine, wort becomes beer through fermentation. The yeast used has the job of converting fermentable sugars into alcohol and carbon dioxide. Every yeast strain – and there are up to 1,000 different ones – works slightly differently.

The yeast used for brewing therefore has a significant influence on the subsequent character of the beer. That's why we at Mönchshof breed our own pure yeast cultures from proven quality yeast strains and keep this a closely guarded secret.

3.1 Top-fermented and bottom-fermented yeast

Basically, two different types of brewing yeast are used depending on the style of beer:

As the name suggests, top-fermented yeasts are used for top-fermented beers such as fruity, fizzy white beers, ales, Kölsch and Altbier. They ferment best at a warm 18 – 22°C. Once its work is done, top-fermented yeast settles at the top in the frothy layer of the beer.

Most other beer varieties are fermented with the various bottom-fermented yeasts. These so-called “lager” yeasts are more reserved and therefore better suited to soft, less floral, mild and fine aromatic beers. They work at a cool 8 – 13°C and settle at the bottom at the end of the fermentation process.

3.2 Yeast & clouding

Some of our Mönchshof speciality beers are unfiltered and naturally cloudy. This means that exclusively natural proteins and tannins from malt and hops, but also yeast, remain in our speciality beers after long, cold storage. Despite what people used to say, this clouding isn't a sign of poor quality – quite the opposite. Unfiltered beers, such as our Zwickl or Kellerbier, still contain all the secondary metabolites, the health-giving ingredients of yeast, and have a particularly full flavour as a result.

Just remember to gently tilt the bottle up and down when pouring the beer to distribute all of the suspended particles evenly in the glass. Then you can enjoy your beer to the full!