Our brewing process

The essential steps of brewing beer have hardly changed since the Middle Ages – and that's a good thing! Click through the individual steps and learn how our Mönchshof beers are brewed: Unadulterated, delicious and tried and tested for centuries.

1

2

3

4

1. Malt

First soak, then germinate, then dry – cereal grains go through this process within a week on their way to becoming malt.

![[Translate to Englisch:] Mönch schrotet](/fileadmin/user_upload/brauprozess/brauprozess_schroten.png)

2. Grinding

Dried and ground malt grains give the beer its body and colour.

3. Brewing water

Only pure water of drinking water quality and with a low calcium content can be used for brewing water.

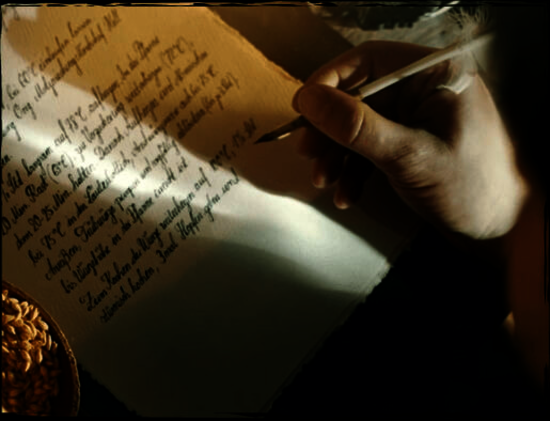

4. Mashing

The malt grains are mixed and mashed with water to release all the essential substances for brewing.

5

6

7

5. Lautering

The husks are separated from the liquid wort.

6. Hops

Hops belong to the Mulberry Bush family. They have been an essential part of every beer since the Bavarian purity law.

![[Translate to Englisch:] Mönch am Braukessel](/fileadmin/user_upload/brauprozess/brauprozess_kochen.png)

7. Boiling

Hops are added to the boiling wort.

8

9

10

11

8. Cooling

The wort is cooled down to 10°C.

9. Yeast

All Mönchshof yeasts are purebred yeasts – and their secrets are closely guarded. They are responsible for giving each speciality beer its unique flavour.

![[Translate to Englisch:] Mönch beim Gäreprozess](/fileadmin/user_upload/brauprozess/brauprozess_gaeren.png)

10. Fermentation

Adding yeast results in formation of carbon dioxide and alcohol.

11. Maturation

Each beer needs a specific resting and storage time.

12

13

14

12. Filtration

Leftover yeast and cloudy matter are filtered out for a crystal-clear beer.

![[Translate to Englisch:] Mönch füllt Flaschen ab](/fileadmin/user_upload/brauprozess/brauprozess_abfuellen.png)

13. Bottling

Once the fermentation process is complete, our beer is stored in kegs or bottled in our classic swing-top bottles.

![[Translate to Englisch:] Mönch bei der Brotzeit](/fileadmin/user_upload/brauprozess/brauprozess_geniessen.png)

14. Enjoyment

Whether you drink them at home, in a restaurant, in Franconia's beer cellars or in the great outdoors – we hope that you enjoy our delicious speciality beers! Prost!